Blue Diamond Attachments has rolled out a new eight-model lineup of Extreme Duty Series 2 Cold Planers for both high- and low-flow skid steers and compact track loaders.

The self-leveling cold planers are designed for road surface milling, concrete scarification and asphalt removal applications. Milling widths range from 14 to 48 inches, and milling depths range from 4.3 to 6.7 inches, depending on the model. They have a working speed of up to 16.4 feet per minute.

Blue Diamond lists the following key features:

- The self-leveling system ensures a consistent milling depth regardless of ground contour or machine position.

- Independent depth adjustment on the right or left, available in mechanical and hydraulic configurations, enables precise surface matching and side-by-side passes.

- Standard hydraulic side shift functionality allows flush milling against walls and other obstacles.

- Multiple drum options with different widths and teeth layouts accommodate various applications.

“By combining precise depth control with exceptional stability and versatility, we’re enabling operators to achieve superior results across a wide range of applications, from pothole repair to complete surface removal,” said Drew Truan, chief operating officer at Blue Diamond Attachments.

Milled material remains in the work area. All models have an optional dust suppression spray system and clear depth indicators.

The line’s robust construction and direct-drive hydraulic motors ensure reliable performance while minimizing maintenance requirements, the company says.

All Blue Diamond cold planers come with the Blue Diamond Satisfaction Guarantee and a 1-year warranty.

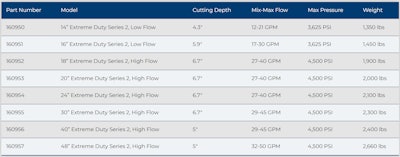

See the chart below for individual model specs:

Blue Diamond Attachments

Blue Diamond Attachments